Vulcan Equipment designed its new combi oven with K-12 schools in mind and the result is an easy-to-use oven with repeatable cooking results.

Combination ovens, often shortened to “combi,” bring together a conventional convection oven and steamer so that chefs can use one piece of equipment, saving space, money and time in the kitchen. A combi oven can also use hot air and steam at the same time, creating flexibility for nearly all cooking styles including steaming, poaching, roasting, baking, blanching, rethermalizing and proofing. The Dine Company team recently got a first look at Vulcan’s entry into the combi market at the Louisville, Ky.-production plant where they are engineered and assembled.

Vulcan designed their model specifically for school kitchens, conducting a lengthy research phase to learn the needs of school kitchen operators before designing their new line. While many combi ovens on the market have programmable, touch screen interfaces, Vulcan’s deep dive with a focus on K-12 kitchens led to simpler, intuitive design with only three knobs.

“You don’t have to be afraid of our combi,” said Kenny Graven, business development manager for Vulcan’s oven and heated holding divisions. “It looks the same as a convection oven. And these school operators have been in front of a convection oven for sometimes 30 years.”

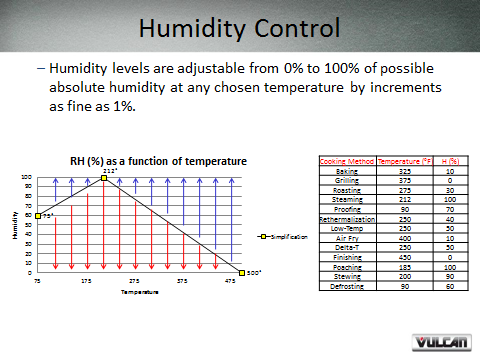

Humidity levels are linked to the temperatures associated with the most common cooking techniques, simplifying the user experience when using a new Vulcan combi. The user can also manually adjust the humidity level if they choose.

Vulcan’s big secret is linking temperature and humidity, two of the three variables in the cooking process, together. In researching the project, Vulcan identified the most likely cooking styles and connected the appropriate humidity level to the temperature setting. While the two are not locked – you can move the humidity level to whatever percentage you’d like with the turn of a knob – this pre-set offers a general starting point that is often what the operator seeks. From there, all you have to do is set the final variable, time, with the turn of a knob and you’re ready to cook.

The Vulcan combi accommodates full-size sheet pans and is made to handle items seen in a school cooking setting – pizza, French fries, hamburgers, chicken patties, steamed vegetables – that also lend themselves to other large-scale serving operations like senior care, prisons or catering.

These units are made at Vulcan’s factory in downtown Louisville, Kentucky in the Portland neighborhood. Materials are shipped in and no metal is broken at the facility, streamlining the building process. Keeping the assembly process in Louisville as simple as possible has allowed Vulcan to hold the line on price and uphold a low warranty rate on its ovens.

“You’ve got to be low-labor these days or you’re going to be building them in China,” Graven said.

If you are a school employee and would like a chance to win a new Vulcan combi, please email Dine Company by Nov. 15. Contact us with questions or to set up a demonstration to help you learn if a combi oven is right for your school or foodservice operation.